When we consider things we utilize every day-- cars and trucks, cooking area home appliances, electronic devices, and also the tiny parts inside our gadgets-- it's easy to ignore the processes that make them feasible. Among the unsung heroes of modern-day manufacturing is metal stamping, a powerful method that forms steel into precise, useful components. Though it's frequently hidden behind the scenes, this technique plays a central function in making our day-to-days live much more effective, comfy, and connected.

Understanding the Art Behind Metal Stamping

At its core, metal stamping is the procedure of transforming level steel sheets right into specific shapes via force and precision. This isn't a one-size-fits-all procedure; it involves several methods like flexing, punching, creating, and embossing-- each selected for the task handy. Every bend and cut is performed with incredible precision, guided by the tools and passes away crafted for the job.

This process requires more than just machines-- it needs a skilled team and progressed innovation. The artistry of tool and die shops hinge on creating personalized dies that enable the specific reproduction of parts, down to the tiniest information. Whether generating simple brackets or complex automotive components, accuracy is non-negotiable.

Just How Metal Stamping Powers Modern Living

Look around your office or home and you'll discover countless items brought to life by metal stamping. The structural frame of your dish washer, the connectors in your smartphone, the bracket holding your cars and truck's dashboard-- all these components owe their presence to stamped steel.

In the auto world, the demand for longevity and consistency makes progressive die marking a favorite. This technique entails a collection of terminals, each doing a special function as the metal advances through journalism. It's suitable for high-volume runs and makes sure each item satisfies exacting requirements.

However it doesn't quit with cars. In the clinical field, where integrity can be a matter of necessity, metal stamping is used to craft medical devices and gadget components. In the aerospace sector, marked components should withstand severe problems while fulfilling tight resistances. The same is true in consumer electronics, where space-saving, high-functionality designs ask for stamped steel elements that are both light-weight and solid.

Precision, Speed, and Reliability: Why Metal Stamping Matters

So why has metal stamping come to be such a best method across so many industries? Firstly: speed. Once the dies are established, thousands of the same components can be generated with little variant. This degree of repeatability is essential when uniformity matters.

Then there's the question of cost-effectiveness. Typical machining could take longer and entail more product waste. Yet marking, particularly when performed with progressive die modern technology, keeps production scooting and successfully. It's one of the most intelligent means to meet high-volume production goals without giving up top quality.

The integrity of this procedure additionally can't be overstated. When you're creating thousands-- or even millions-- of parts, a tiny flaw can end up being a big problem. That's why partnering with a knowledgeable tool and die company is so essential. The ideal group makes certain every component is made to spec, each time.

Inside the World of Tool and Die: What Makes the Magic Happen

Behind every fantastic stamped item is a team of professionals crafting and preserving the tools and passes away that make production possible. In numerous methods, tool and die shops are the heart of the operation. They design the passes away, fix any kind of manufacturing problems, and ensure the stamping procedure runs smoothly throughout.

This level of workmanship isn't attained overnight. It takes years of hands-on experience, training, and a deep understanding of products and equipment. These professionals are problem-solvers and innovators, continuously refining their approaches to boost rate, decrease waste, and increase product top quality.

While automation has actually made fantastic strides, there's still no page substitute for the insight and adaptability of human experts. From dealing with CAD software to improving a model, the job performed in tool and die shops merges contemporary innovation with typical accuracy engineering.

Advancing With Industry Demands

As industries remain to develop, so as well does metal stamping. Suppliers are checking out new alloys, tighter resistances, and much more small styles. With these shifts come new difficulties-- and possibilities.

For instance, as electrical vehicles (EVs) gain appeal, there's a growing requirement for lightweight elements that can stand up to high performance and severe temperature levels. Marking satisfies these needs, giving solid yet reliable components without including mass.

Smart home gadgets and wearables likewise rely on stamped steel parts to maintain their accounts streamlined while protecting delicate inner components. The increase of miniaturization is pushing the limits of what metal stamping can do, and the very best tool and die company will certainly always prepare to introduce along with industry patterns.

The Future Is Stamped

What's most interesting is just how this technology continues to forge ahead. With advanced products, automation, and information analytics, the future of metal stamping looks also brighter. These tools will help producers react faster to market adjustments, boost sustainability, and continue enhancing efficiency and style.

Yet, even as the sector progresses, one truth remains: top quality issues. It's the dedication to excellence from skilled experts in tool and die shops that ensures each stamped product executes precisely as it should, whether it's powering your morning coffee equipment or a satellite in orbit.

Remain Connected to the Process That Shapes Your World

From the smallest electronic adapter to the framework of your vehicle, metal stamping is anywhere. And as technology advances, this necessary production process only grows in significance and capacity. Curious regarding exactly how the day-to-day items around you are made? Or exactly how advancement is driving smarter, extra efficient production? Follow our blog site to remain in the loophole.

We're just starting-- make sure to inspect back typically for more behind-the-scenes tales, market understandings, and updates on exactly how progressive die, tool and die shops, and professional tool and die company teams are forming the world, one stamped part at once.

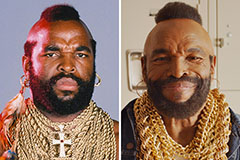

Mr. T Then & Now!

Mr. T Then & Now! Andrew Keegan Then & Now!

Andrew Keegan Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Mary Beth McDonough Then & Now!

Mary Beth McDonough Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now!